New Equipment

Central States Machinery is fully committed to ensuring your machinery needs are met. Our product line encompasses Fabrication, HVAC, Precision Machinery, and Metal Processing Systems. From start to finish, customer service is our TOP PRIORITY. Our knowledgeable sales force guides you through the sales process. Experienced and professional technicians train you and your staff on site. All are available to support you long after the sale.

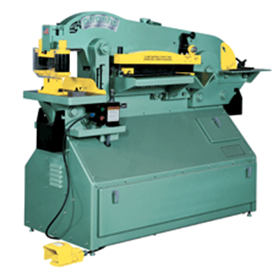

The Piranha Model P-90 picks up where the P-65 leaves off – for applications requiring more tonnage.

Standard Equipment

- Complete Punching Attachment with split dove tail mounting

- 5 Punch and Die Sets

- Automatic Urethane Hold Down on the Punch Stripper and on Angle

- Plate and Shear Bar

- Front and rear 5 position joy stick controls (electric) with jog up & down, fast up & down, neutral

- Remote Electric Foot Switch that can be connected at either end of the machine

- Electric Limit Switches that can be set for stroke control when using foot control

- Set of Round Bar Knives (2 way) (customers choice to 2)

- Set of 14.50 Plate Shear Knives (4 way)

- Extra Blank Knife to extend shear to 18”

- Set of Angle Knives (8 way top) (4 way bottom)

- Set of Coper Knives (2 way top) (4 way bottom)

- Chip Buckets (2 each)

- Extra Oil Filter

- Coupling Wrench & 3/8” Allen Wrench

- Integral Lifting Lug for instant portability

Available Attachments;

• Tube Notching Attachment • Channel Die Block • Bending Attachments

• 28XX Punch Attachment • Press Brake Tooling Holders • Quickset Gauging Tables

• Channel Shear • Bar Bender • Mechanical Backgauge • Electric Backgauge • 1-1/2” Oversize Punch Attachment

• Roller Feeder Tables

|

Throat Depth |

10” |

Coper-Notcher (Tons) (Max. Material) |

75 3-1/2” x 5” x 3/8" |

|

Open Height |

15” |

Optional Bending Attach. |

12”, 24” |

|

Closed Height w/o Die Block |

10-1/8” |

Punch End - Strokes Per Minute Optional Speed-Up Kit |

32 @ 3/4" 45 @ 3/4” |

|

Stroke Length |

4-7/8” |

Work Station Height (approx.) |

42” |

|

Platen Table Size (D-W) |

12” x 21” |

Hydraulics Pump GPM System R/V PSI |

10.5 2,900 |

|

Punch Hole Size (Max Material) Max. Hole Size (Material) |

90 Tons 1-1/8” (1”) 5” (3/16”) |

Fluid Capacity (gal.) |

25 |

|

Plate Shear

|

18” Long 1” x 8” 3/4” x 12” 1/2” x 18” |

Motor Std. 230/460 3 Ph. 1800 RPM Opt. Phase Voltage Available |

10 HP 3 Ph |

|

Angle Shear |

5” x 5” x 12” |

Dimensions (Net) W-L-H Approx. |

31” x 79” x 64” |

|

Bar Shear Round (min. to max.) Square (min. to max.) |

1/2" to 2” 1/2” to 1-3/8” |

Weight (Net) LBS. Approx. |

4,250 |